About Us

OUR BUSINESS

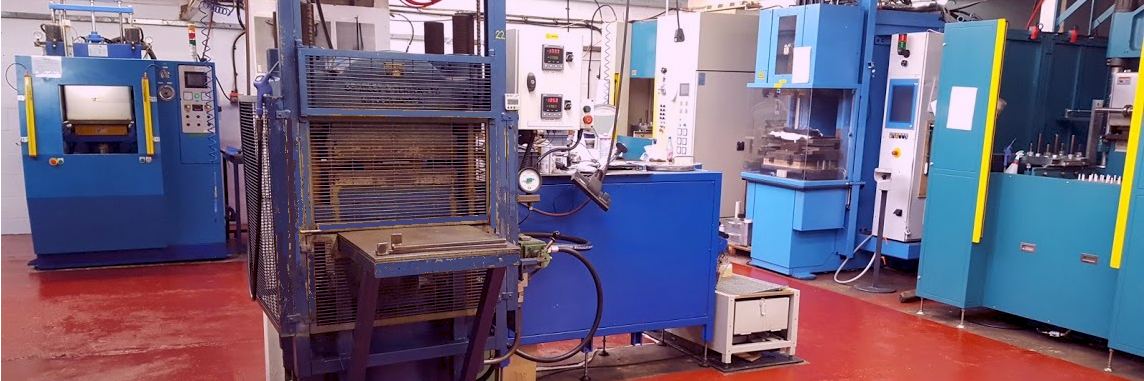

Butser Rubber is one of the leading rubber moulding manufacturers in the UK. Our operations and manufacturing centre is based in Liss, Hampshire where we have grown in both size and knowledge. Our diversification of market segments within the rubber industry has demanded investment in state-of-the-art machinery to fulfill customer requirements. Our bespoke rubber components can be found in a wide range of industries from Medical to Formula 1. We are able to work with engineers and designers from concept through to production to ensure product feasibility, competitive pricing and short lead times.

OUR PEOPLE

Butser Rubber employs a number of staff at our manufacturing centre in Liss, Hampshire. Our staff are experienced specialists in the rubber moulding process, utilising our state-of-the-art machinery to produce industry leading custom rubber mouldings. Our staff are at the forefront of our rubber moulding business, and ultimately provide the dedication and creativity required to ensure successful outcomes for our customers projects.

OUR HERITAGE

Butser Rubber was established in 1977 by Derek and Jean Winterbottom. We now have a history exceeding 40 years while still retaining our roots as a family run enterprise. Our teams determination combined with the entrepreneurship of our three generation strong management team has led to successful growth of the company. We manufactured our first Formula 1 component in 1979 and have since provided parts to many race categories including F1, Le Mans Prototypes, British GT Championships and World Rally Championship. We also have a long history of providing rubber solutions to the Marine and Aerospace industry for commercial and military projects. Our diversification over the last 15 years has increased our capacity to provide quality products to industries such as Health Care, Filtration, Industrial, Agriculture and Renewable Energy.

OUR AREAS

OF EXPERTISE

Our story

2021

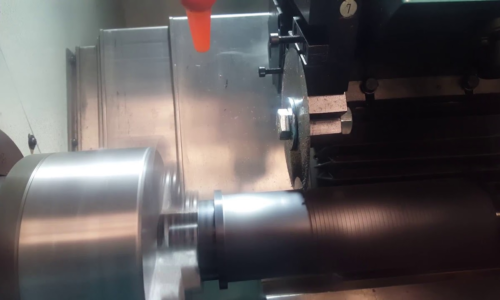

Butser Rubber take delivery of the second production robot (Cobot) after the success of the first in 2020. Most Lathe operations are now run fully autonomously using Cobots.

Also a major environment mile stone, Butser Rubber take delivery of their first injection rubber cold runner system. “100% material saving in the material runners”. Immediately resulting in ‘zero landfill’ from those particular product lines. Butser plan to order a second cold runner for delivery later 2021 to build on these excellent results.

2020

New purpose built factory unit on Mint Road site is completed. Providing an extra 25% extra working space with improved lighting and building insulation for improved manufacturing stability. Butser Rubber take delivery of their first production robot on the shop floor in the new unit.

We were very proud to be part of the ‘Covid Ventilator challenge’ project and be selected to supply the rubber bellows in the ventilators helping the NHS with its urgent requirements. #ThankyouNHS

2019

Butser Rubber take delivery of their first high speed laser cutting system. This laser cutting machine has now become the back bone of our rapid sample capability and inhouse tool making.

The high speed laser broke Butser Rubber into the same day RP (Rapid Prototyping) market. Samples in most rubbers and organic materials to extremely high tolerances and meeting CAD design without the need of tooling. Looking back, How did we work without it?

2018

Butser Rubber take delivery of 2 brand new vertical injection rubber moulding machines pre-ordered with Robot interfaces ready for industry 4.0.

2017

Butser expect to take delivery of a new Microshot Injection Moulding machine due in November 2017. This aims to increase manufacturing capability of precision components.

2016

Butser Rubber purchased advanced high speed ‘Spin Trim’ technology to reduce Cryogenic trimming lead times.

2015

Butser invest in their second EFE high speed injection moulding machine. Butser provide on-going investment support into new rubber moulding technology to decrease cycle times, and further automate the manufacturing process.

2014

Butser Rubber proudly take delivery of 4 new vacuum compression moulding presses to support high running OEM demands along with greater production precision.

2012

Butser invest in their largest compression moulding machine to date. Creating increased production speeds, process stability and cycle times that reduce part prices. Install new (Version 9) ‘123insight’ ERP and MRP software to provide more in depth batch traceability, with the ability to track serial numbers and material batches via barcode for automotive and aerospace applications.

2011

Butser Invest in their first ‘Computer Controlled Rubber Extruding Machine’ for automatically adjusted precision blanking. This was the First in the UK! Butser Rubber purchase their first ‘Automatic Inspection Machine’ using ‘Video Edge Detection Systems’ for Automotive and Aerospace inspection requirements providing electronic SPC & MS capability.

2010

Butser’s expansion supports investment into Vacuum Chamber presses and Gasket cutting Machines for greater capacity and in-house capability.

2007

Butser install 123Insight (Version 6) MRP Software computer system for: Stock management, Full traceability via electronic factory transactions and MRP.

2006

Mint Road Site increased to bring subcontracted work in house.

2003

Butser first visit the Autosport show in the NEC Birmingham.

1999

Expanded to second factory in Station Road.

1977

Founded by Derek and Jean Winterbottom at 21 Mint Road.